Effective Techniques for Using Asphalt Patch Kits

Key Takeaways

- Understanding the types of asphalt patch kits available.

- Preparation of the area is crucial for a smooth finish.

- Using appropriate tools improves durability and appearance.

- Follow manufacturer instructions for the best results.

- Regular maintenance prolongs the life of repairs.

Asphalt patch kits are essential tools for maintaining and repairing your asphalt surfaces. Whether you're a contractor or a DIY enthusiast, knowing how to use these kits effectively can save you both time and money. This guide covers practical techniques and tips for using various asphalt patch kits, ensuring durability and a smooth finish.

Types of asphalt patch kits

Before diving into techniques, it's important to understand the different types of asphalt patch kits available.

| Patch Kit Type | Best For | Features |

|---|---|---|

| Cold Patch | Small cracks and potholes | Ready to use, no heating required |

| Hot Mix | Larger repairs | Requires a heating source, long-lasting |

| Sealant Patch | Surface sealing | Improves the appearance and protects the surface |

Preparation for effective repairs

Preparation is a critical step in achieving a successful asphalt repair. Here are some key steps:

- Clean the area: Remove debris, loose asphalt, and dirt.

- Inspect the damage: Assess the cracks and potholes to choose the right patch kit.

- Cut edges: If needed, square off the edges of the damaged area for better adhesion.

Using Asphalt Patch Kits

Application Techniques

When applying asphalt patch kits, the method can greatly impact the longevity and effectiveness of your repair.

Tips for Application

- For cold patch, follow the manufacturer's instructions regarding thickness and compaction.

- Use a tamper or vibrating roller for earth contact post-application.

- For hot mix, ensure that the mixture is heated to an appropriate temperature.

- Use a trowel for smooth edges and an even surface finish.

- After applying, allow sufficient curing time as recommended by the manufacturer.

Featured Products for Asphalt Repair

To help with your asphalt repair projects, here are two highly recommended products:

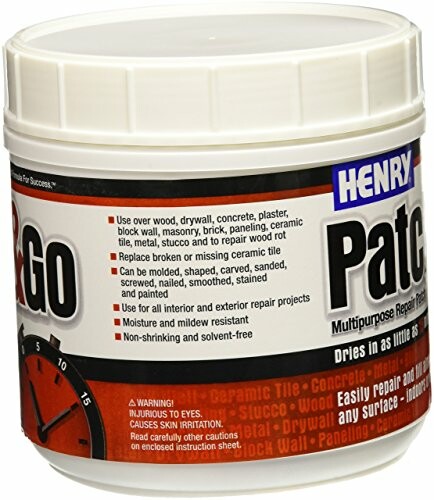

12226 LB Go Patch Kit, 1 lb

This product adds great value, is highly durable, and very easy to use. Manufactured in the United States, it's perfect for your asphalt repair needs.

Learn MoreMagic Crack Filler 2LB Concrete Tan

A DIY-friendly solution to fill in concrete cracks effortlessly. Simply add water for a smooth finish, achieving professional results with minimal effort.

Learn MoreMaintenance & Follow-Up

After repairing your asphalt surface, here's how to maintain it:

- Regularly inspect for cracks or damage.

- Keep the surface clean from debris and oil.

- Seal coat every few years to protect the asphalt.

Conclusion

Utilizing asphalt patch kits effectively can extend the life of your asphalt surfaces. With the right techniques, preparation, and products, your pavement can look like new again. Explore more of our resources like Asphalt Paving Techniques and Sealants and Crack Fillers for additional guidance.

Pros

- Cost-effective solution for minor and major repairs.

- Improves the appearance of your pavement.

- Increases the longevity of your asphalt surface.

Cons

- Some products may require professional application.

- Potential for improper use leading to ineffective repairs.